Vacuum-Membrane Press

TRANSFORM - FORMA

Category:

Surface coating and pressing systems, cutting and sizing machines, shaping, milling and surface correction systems

This product is provided by the company AS METAL AĞAÇ MAK.SAN.VE TİC.LTD.ŞTİ. . Please contact for more information.

Product Description

TRANSFORM PLUS

As standard single machine, request and are produced as a pair of trays. Standard tray size 1400 x 2500 mm’dir. Tray movements made by hand. The operating cycle takes place completely automatically during Printing.

in total, 3.5 +1 kg / cm2’This model works with light pressure, 0.2 mm ve 0.4 kaiığnlıg mm PVC foil in all kinds of mat and is ideal for natural veneer cover jobs.

Also in the medium quality glossy PVC (high gloss) also be used to cover jobs. necessary to machine the upper plate removably mounted on the rubber-silicon membrane suspended after a few minutes.

Thanks to the auxiliary air chamber, No need to install on the machine is to dismantle the membrane and membrane-membrane studies. The transition between operating formats, easily done with a button on the machine.

FORMA PLUS

Designed primarily as a vacuum-membrane press, this model has all the features of the Transform model.

Table movements are also automatic in the Forma model, which is produced as 1400 x 3200 mm and double table as standard. Therefore, this model operates fully automatically, if desired, it is also possible to manually control the entire machine by switching to manual mode.

This machine, which works with a total pressure of 6 + 1 kg / cm2, gives excellent results for all kinds of matte PVC cover and natural veneer cover works of 0.2 mm, 0.4 mm and 0.6 mm thickness.

It is specially designed for high gloss cover works with a pressure of 6 + 1 kg / cm2. This ensures that glossy PVC foils that are more difficult to shape are pressed under lower temperatures. Adhesive PVC foil does not lose its brightness, surface so called the orange surface disappears and gives excellent results.

GENERAL FEATURES

Carries the engraved thermoplastic foil, veneer or the flat surface glued to panel. vacuum, membrane, Membrane presses the vacuum-operated in different functions.

Vacuum-saving feature allows the membrane by allowing material to be used as part of pvc’ıer. The oil-heated hotplates, Each serpentine or solid surface due to the special uniform heat distribution plate system is provided. Printing takes place during the operating cycle is completely automatic. For this multi-function machine is supported by a PLC. vacuum, to select the desired program type membrane or a wide variety of work modes are possible for the vacuum membrane. Memory may be made to the programs on the operating cycle and this provides great convenience for users. Different thickness and / or programs made for different types of PVC color after memorized, from now are easily installed and working memory can be initiated when desired.

All Transactions 7 inch touch screen and Turkish operated was made very easy for users with visual programming. Diaphragm or membrane-pressure selection is made with a single button on the control cabinet.

Other Products of the Company

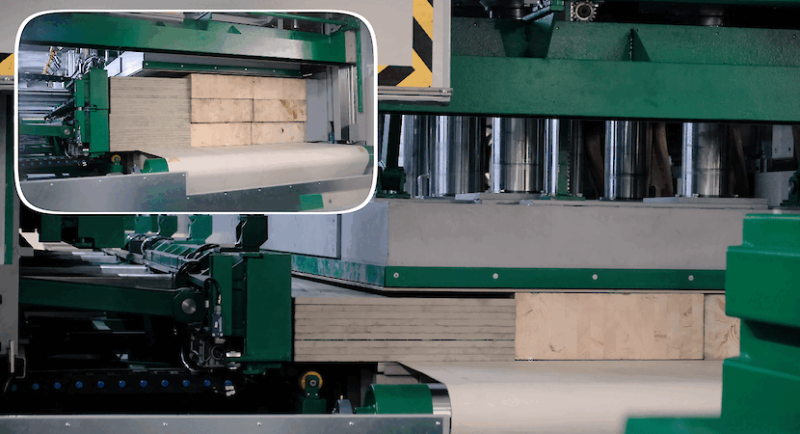

See AllGLT & CLT Solid Wood Panel and Beam Lamination Line

GLT & CLT Solid Wood Panel and Beam Lamination Line

Automatic Foil and Natural Veneer Press Lines

Automatic Foil and Natural Veneer Press Lines

KOBOT

INDUSTRIAL ROBOTIC ARM

Similar Products

See AllMULTI-SLICING MACHINE

MDF MULTI-CUTTING MACHINE (MDF 105)

L shape machine

door profile L shape profile machine line

Plug and cut

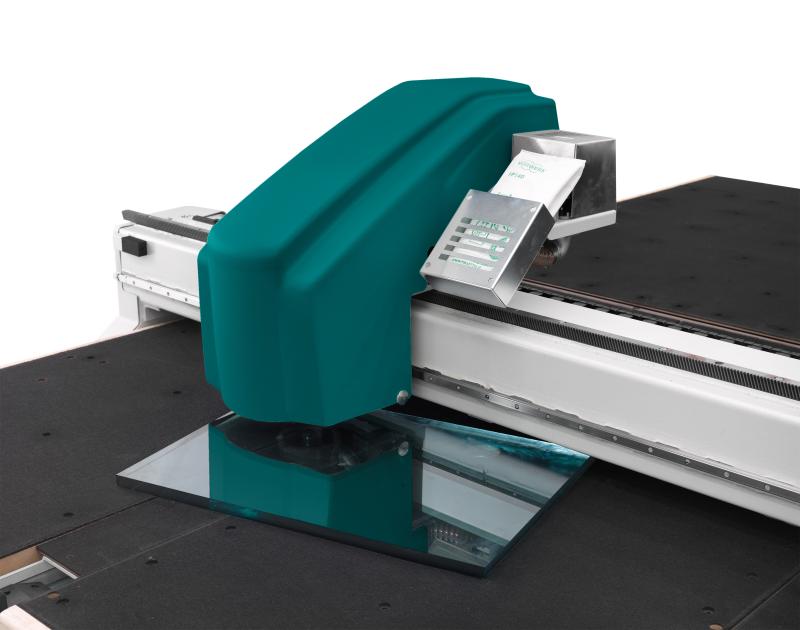

Intermac Cut Go M

Continuous press