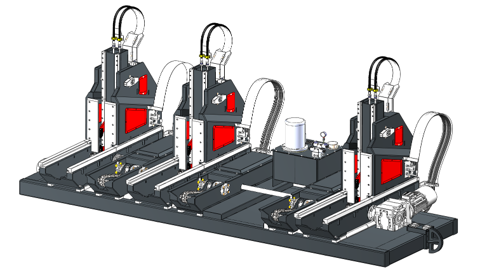

CML/2/250 Multiripsaw Machine

Multiripsaw Machine

Category:

Log processing and cutting systems

This product is provided by the company CENA MAKİNA BİLGİSAYAR VE YAZILIM SİS. SAN. TİC. A.Ş. . Please contact for more information.

Product Description

Specifications

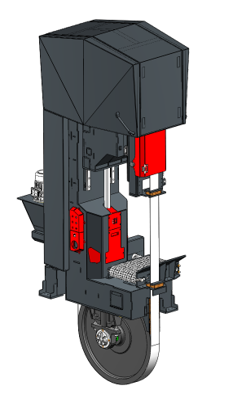

Lower and upper saw system that can be adjusted according to cutting thickness with a digital system.

With this system, the lower and upper saws cut equal amounts, and the main engines meet the equal load, giving fixed saws 20% higher performance than machines.

Saw spindle made of special steel, hardened and ground.

Pallet system made of special alloy that provides a smooth cutting surface in the feeding direction of the machine, 4 pneumatically driven special alloy rollers to remove the cut products at the exit section.

Safety nails and curtain system made of special alloy steel, 2 rows at the top and 1 row at the bottom, against parts flying from the machine entrance and kickbacks.

SCHNEIDER ELECTRICS PLC control system with 12” screen, which enables the positioning of the saws and the upper pressure system.

Adjustable guide system at the machine entrance to cut clean products on 3 sides without wastage.

Automatic lubrication system for pallet system.

With the error detection page, possible errors can be diagnosed very quickly.

Possibility of remote connection via Wi-Fi, which shortens error detection times and solutions and does not require the employment of costly expert personnel.

Technical Specifications

Max. Cutting Height : 250 mm

Min. Cutting Height : 20 mm

Max. Cut Width : 450 mm

Max. Working Width : 750 mm

Min. Cut Length : 800 mm

Max. Cut Length : 6000 mm

Saw Diameter : Ø400 (Ø300-Ø350)

Saw Rotation Cycle : 3000 d/min

Saw Bore Diameter : Ø 90 mm

Max. Feed Rate : 40 m/min

Main Power : 2×75 kW

Up and Down Rollers Movement : Electric Motor

Upper Roller Movement : Pneumatic

Pallet Feeding System : Electric Motor

Up and Down Movement of Circular Saw : Electric Motor

Lubrication System : Automatic

Weight : ~ 7000 Kgs

Other Products of the Company

See AllBoard Edger Machine

Board Edger Machine

Conveyor Systems

Conveyor Systems

Hydraulic Log Carriages

CLC/120/300 – 3 Hydraulic Log Carriages

Hydraulic System Band Saw

CLB/120 – Ø1200 Hydraulic System Band Saw

Similar Products

See AllConveyor Systems

Conveyor Systems

Hydraulic System Prism Machine H.P.M.350

PRISM MACHINES

Horizontal Log Bandsaw

UHYB_120_PLUS HORIZONTAL LOG BANDSAW

Board Edger Machine