| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

CENA MAKİNA BİLGİSAYAR VE YAZILIM SİS. SAN. TİC. A.Ş.

İNÖNÜ MAH. 139. SOKAK NO: 46 / TORBALI / İZMİR / TÜRKİYE

|

Contact Info: +90 535 346 0092

|

Hall: 2

Stand: 235

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Continuing its activities with its expert staff in the supply of complete and diversified machinery and equipment, Cena Makina A.Ş provides safe and innovative solutions in the processing of logs and woods. It establishes fully automated turnkey factories for medium and high capacity log processing plants.

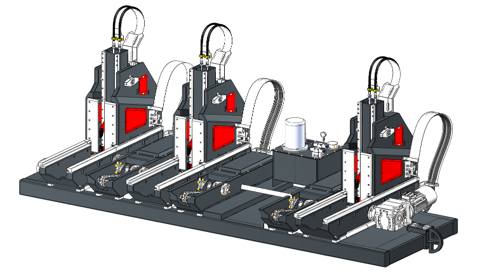

CPM/400 Prism Machine is specially designed to cut logs between 150-400 mm in diameter and 2-6m in length with the help of a circular saw. It is used to cut logs vertically to length with circular saws driven by independent electric motors on four separate shafts in the machine. Machine; It consists of 3 modules: input module, cutting module and output module. Right and left saws can be positioned in millimeters according to the diameter of the log. As an option, right and left saws can be automatically positioned according to the diameter of the log. CPM/400 Prism Machine, which can cut at high speed and efficiency, is suitable for cutting logs of various lengths (1.2-6 m) according to customer demand, and is preferred in wooden pallets, construction timber and joinery timber production workshops Technical Specifications Max. Log Diameter : 400 mm Min. Log Diameter : 150 mm Max. Cutting Height : 390 mm Min. Cut Width : 78 mm Max. Cutting Width : 240 mm Min. Cut Length : 2000 mm Max. Cut Length : 6000 mm Circular Saw Diameter : 650 mm Main Engine : 4×45 kW Other Engines : 7 kW Weight : ~ 13000kg

Specifications Lower and upper saw system that can be adjusted according to cutting thickness with a digital system. With this system, the lower and upper saws cut equal amounts, and the main engines meet the equal load, giving fixed saws 20% higher performance than machines. Saw spindle made of special steel, hardened and ground. Pallet system made of special alloy that provides a smooth cutting surface in the feeding direction of the machine, 4 pneumatically driven special alloy rollers to remove the cut products at the exit section. Safety nails and curtain system made of special alloy steel, 2 rows at the top and 1 row at the bottom, against parts flying from the machine entrance and kickbacks. SCHNEIDER ELECTRICS PLC control system with 12 screen, which enables the positioning of the saws and the upper pressure system. Adjustable guide system at the machine entrance to cut clean products on 3 sides without wastage. Automatic lubrication system for pallet system. With the error detection page, possible errors can be diagnosed very quickly. Possibility of remote connection via Wi-Fi, which shortens error detection times and solutions and does not require the employment of costly expert personnel. Technical Specifications Max. Cutting Height : 250 mm Min. Cutting Height : 20 mm Max. Cut Width : 450 mm Max. Working Width : 750 mm Min. Cut Length : 800 mm Max. Cut Length : 6000 mm Saw Diameter : Ø400 (Ø300-Ø350) Saw Rotation Cycle : 3000 d/min Saw Bore Diameter : Ø 90 mm Max. Feed Rate : 40 m/min Main Power : 2×75 kW Up and Down Rollers Movement : Electric Motor Upper Roller Movement : Pneumatic Pallet Feeding System : Electric Motor Up and Down Movement of Circular Saw : Electric Motor Lubrication System : Automatic Weight : ~ 7000 Kgs

It is a perfect complement to obtain the desired width product from the edged plates. While providing ease of use with its simple, compact and versatile designs, it can be integrated into the existing facility of any business thanks to its easy assembly. Models with 120-160 mm cutting heights Possibility to apply 2 or 3 saws to the movable and fixed sleeve Manual or automatic feeding Automatic fueling Possibility to process 1000 mm wide products Optional equipment; PLC controlled manual or automatic feeding Up to 3 axis movable saw option Removal of waste from the system thanks to separator arms Cutting easily and in the most efficient way with the alignment arms. Technical Specifications Max. Cutting Height : 120 mm / 160 mm Min. Cutting Height : 15 mm Max. Cut Width : 800 mm Max. Working Width : 1000 mm Min. Cut Length : 800 mm Max. Feed Rate : 40 m/min Saw Rotation Cycle : 3000 rpm Upper Rollers : 2 x 240 Bottom Rollers : 5 x Ø135 mm (120) : 6 x Ø135 mm (160)

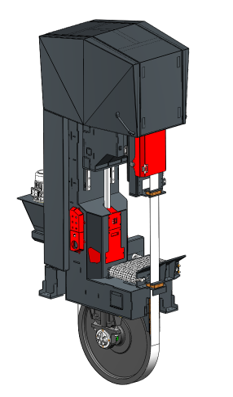

Specifications Easy remote controlled via 2 joystick with 6 buttons Selectable conditions of hooks-turning devices The forward and backward movement of the carriage is done by an electric motor reducer with a speed control device. System with steel rope and drum mechanism. Depending on the log type, the hook tightening pressure can be adjusted at 2 different pressures. Headblock positioning speed 300mm/sec Hydraulic system hook movement. Automatic dosing and central lubrication system. Automatic warning system at hydraulic unit. (temperature/level/pressure) Multi-axis PLC control system, 12 Schneider brand touch screen Quick positioning with optimized cutting program. Selectable cutting program according to quality, length, price. 100 cutting programs can be saved, each of which can be entered with 16 different thickness values. Checking and detecting problems as quickly as possible with the diagnosis page. Possibility of remote connection via the internet, which shortens error detection times and solutions and does not require the employment of costly expert personnel. Technical Specifications Headblock Speed : 300 mm/sec. Carriage Forward and Backward Speed : 120 m/min. Width of the Carriage : 2200 mm Length of the Carriage : 5000 mm Weight of the Carriage : 7000 Kgs Rail Width : 1220 mm Maximum Opening of Headblocks : 1000 mm Maximum Opening of Hooks : 1000 mm Distance Between Headblocks : 1200 mm 2300 mm Hydraulic Unit Motor : 15 kW Forwarding Electric Motor : 18,5 kW Engine of Headblock Movement : 7,5 kW

Technical Specifications Flywheel Diameter : 1200 mm Flywheel Width : 140 mm Max. Cutting Height : 1100 mm Max. Cutting Width : 650 mm Main Engine : 45 kW Other Engines : 3,7 kW Specifications Automatic pressure controlled saw tension system. Hydraulic system saw nozzle up and down movement. The upper flywheel tilting process is manual. Automatic diesel fueling system for saw and flywheel cleaning Chain waste conveyor at cutting drop point. Pneumatic brake system for stopping the saw in an emergency Switching to emergency mode with the sensor that detects the saw breaking.

Transport and handling technology from the sawmill specialist. In addition to planning customer-oriented conveyor technology for new systems, we also support you in the expansion, modernisation and improvement of your current system with our many years of experience. Log sorting systems Transverse or longitudinal log transport systems Alignment conveyors Stacking systems Pallet stacking / destacking systems

The woodworking industry aims to get the maximum efficiency from the log. CENA Log dimensioning system is designed for you to get maximum efficiency in your cutting line. It measures the diameter and length of the log and controls your cutting lines and stacking lines. In the CENA Log measurement system, logs move continuously on the conveyor chain. It has a measurement capacity of all lengths from 1.2 meters to 6 meters. It works in integration with the CENA prism machine and provides automatic positioning of the saws to the most suitable cutting size according to the log diameter. All measurements are recorded on an hourly and daily basis, thereby providing ease of traceability.

The company has no registered brand information.

TR

TR