| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

KARABUDAK MÜH. MAK. İML.SAN.LTD.ŞTİ.

İnönü Mahallesi Gebze Plastikçiler OSB Mah. 1.Cadde No: 6 / Gebze / KOCAELİ / TÜRKİYE

|

Contact Info: +90 262 646 5262

|

Hall: 3

Stand: 305

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

We Offer Technological Solutions! Innovative and modern solutions for wood and furniture painting, sanding and drying processes. Karabudak Makine who aims to submit the best service to customers all around the world by its innovative self manufactured painting, sanding and drying machines succeed to be a leader on the wood finishing market by developing itself day by day. Karabudak Makine also provides engineering services such as turnkey painting facilities and production automatization to its customers using its expert staff, high technology equipment and innovation. Through its innovative solutions and flexible engineering capacity Karabudak Makine does not only submits its standard machines to its customers but also offers customer-specific solutions. Expert staff, which is created by company owners, warrants Karabudak Makine to be well-known as a reliable solution partner. When Did We Start ? In 2010, founded with 100% Turkish capital by grounding on the quality and customer satisfaction, Karabudak Makine is maintaining its production journey in modern facilities with high technology equipment pool and experienced staff. Karabudak Makine became the market leader in Turkey by growing up rapidly with its innovative approach. Now exporting %70 per cent of its production with its export spurt which started in 2014. What s Our Point Of View ? We obtained as a mission to promote economical improvement of our country with the help of our mark value and high-quality innovative machines by working hardly, professionally and with the conscious of team work philosophy for our satisfied customers, dear business partners, reliable suppliers and also for our personnel. To meet the our satisfied customer requirements the priority of our mission is to create a peaceful, transparent, democratical, profitable working atmosphere, to guarantee the sustainability, to produce environment friendly international competitive high quality innovative improvable machines by using its own resources effectively and aiming minimum cost and the maximum marketable machines. Our Customers Are Our Priority ! As Karabudak Machine KA.MA; We appropriated as a standard principle to meet the customer requirements by guaranteeing the customer satisfaction and answering their all possible negative and or positive feedbacks quickly. We mainly focused on customer requirements while building our working systematic. Our customer satisfaction policy based on meeting the customer requirements, implementing the personnel satisfaction, meeting the legal and administrative requirements, and improving our own standards and meeting the requirements of other interested parts. What Are Our Policies ? As Karabudak Machinery KA.MA; Our occupational health and safety policy aims to build up health and safety based working atmosphere, to pull down the occupational accidents by foreseeing the possible risks, to use resources effectively for safety of manpower health, t

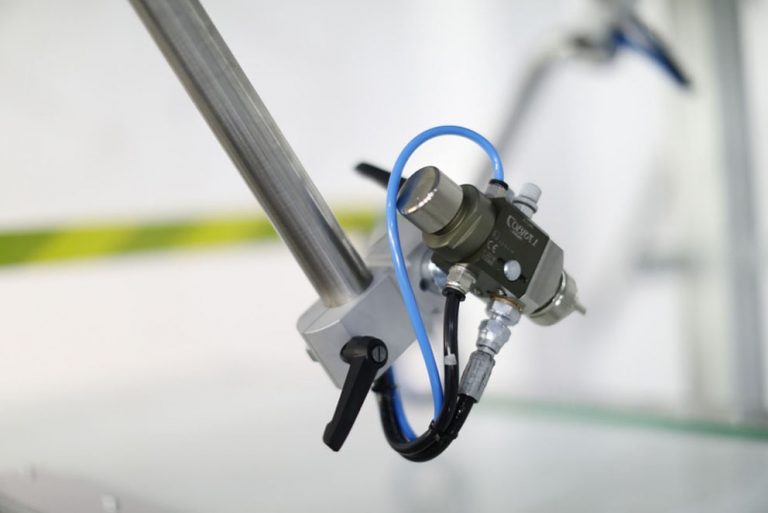

K-BOTIC is a new generation multiaxis painting robot which was designed & developed for robotic painting of panel-shaped products and allows the edge and surface profiles of products to be painted with the same quality as their flat surfaces. Thanks to its flexible design, K-Botic can be configured according to all kinds of needs. It can be equipped up to 2 cartesian robot arms and up to 10 spray guns. PRODUCT SCANNING SYSTEM (SMART CARTESIAN SPRAYING ROBOT) (Image Process and/or Lidor) The patented K-VISION System, which detects the products in 3D at the machine entrance is offered as a standard feature. The system detects the width, height and depth dimensions of the products in millimeters at the machine entrance and automatically prepares the work order for painting in real time without the need for any CAM data. The surface paint homogeneity of the painted workpiece is determined numerically. This data is used to create an additional painting route. CONTROL PANEL Kbotic Smart Cartesian Spraying Robot is equipped with an Industrial PC which allows both to control all functions and operating parameters. These parameters can be saved and loaded on the touch screen PC screen. SPRAYING ARM K-BOTIC is equipped with a 5-axis cartesian arm and 2 airmix guns on the arm as standard. By this means, both paint and glue applications can be made with the same machine. OVERSPRAY FILTRATION K-BOTIC Smart Cartesian Spraying Robot is equipped with an exhaust fan with a flow rate of 18000 m3/h and with an easily maintained and replaced two-stage paper filter. The large filtering surface area guarantees better air distribution, which translates into uniform finishing and a cleaner machine. VENTILATION SYSTEM Inverter controlled tubeaxial fans (6 pcs) which pump air inside the cabin through the F5 filters are placed on the top of the K-Botic. Thus, the cabin pressure is constantly kept in balance and dust entry from the environment into the machine is prevented. Cabin pressure is kept constant at the desired volue with PID by means of a transmitter. AUTOMATIC LUBRICATION SYSTEM This system, ensures the smooth and long-lasting operation of the system by automatically lubricates lineer bearings and guides of the reciprocating arms, is offered as standard . QUALITY CONTROL SYSTEM K-BOTIC can be equipped with an industrial camera and a quality control system at the exit of the machine optionally. This Ka-Ma patented system, takes photos of the painted workpieces and carries out quality control with the help of artificial intelligence, and maximizes the productivity by giving approval or rejection. BELT CONVEYOR WITH PAINT RECOVERY SYSTEM K-BOTIC can be equipped with a belt which is ideal for guaranteeing paintrecovery (thanks to the recovery and cleaning carriage) . This system can provide paint savings of up to %30 in mass production. EXTRA ROBOT ARM (optional) K-BOTIC painting robot can be equipped with two robot arms according to the needs. Painting speed can be doubled or rapid color change can be made as the arms can work independently. 2 arms can work together continuously so it allows painting at very high speeds. TECHNICAL SPECIFICATIONS (SMART CARTESIAN SPRAYING ROBOT) K-Botic Mass: 11750 Kgs. Camera Sliding Conveyor- Mass: 750 Kgs. K-Botic Dimensions: L: 6,600 mm, W: 5,100 mm, H: 3,350 mm. Camera Sliding Conveyor Dimensions: L: 4,100 mm, W: 4,150 mm, H: 2,150 mm. K-Botic Electricity Consumption: 24 kW/h. Camera Sliding Conveyor Electricity Consumption: 1,5 kW/h. Air Consumption: 1,250 L/ min. (Excluding 80 NL Guns) Air Pressure: 6 bar. Aspiration Flow Maximum: 18,000 m³/h. (Inverter Controlled) Aspiration Rate: 1,5-4,5 m/min. (Inverter Controlled) Ventilation Flow: 18,000 m³/h. Ventilation Rate: 1,5-2 m/min. Operating Height (Effective): 150 mm. Operating Width (Effective): 1,200 mm. Operating Lenght (Effective): 2,800 mm. Linear Painting Speed: 1,5-2 m/min. Conveyor Rate (Maximum): 8 mt/min. (Inverter Controlled)

Ka-Ma Cevval Two-Arm Reciprocating Spray Machine, has been designed and developed to achieve high quality finishing on any kind of panel material, is a new generation Automatic Spraying Machine which differs from its equivalents with its superior features and technology. Ka-Ma Cevval, which provides high quality and rapid painting of wood, metal, glass, plastic, fibercement and etc. has two, servo-controlled painting arms. STANDARD FEATURES I TWO-ARM RECIPROCATING SPRAY MACHINE Reading Barrier Sensor Beam ensures a milimetric precision on determining the section which will be painted. It minimises the wastage of paint. Reading barrier is positioned under the motorized feeding rollers. Spraying Arm It s equipped with 2 arms. Cycle speed can be adjusted on the touch screen automatically. Maximum speed of the arm is 150 m/min. Height of the guns can be adjusted easily with the adjustable handle. Cevval has a highly developed painting system. 4, 8 or 12 pcs. automatic paint spray guns can be installed. Gun system of Cevval is designed to quick and easy replacements. Conveyor System Paint on the polyolefin conveyor belt is scraped automatically and can be used again with the paint recovery system. Cleaning system cleans the belt with a solvent and rubber blades make the belt completely dry. Automatic Belt Centring Device The belt also features an automatic centring device to guarantee correct conveyor belt positioning on the high precision carriage. Ventilation System Celullar fan which pumps air inside the cabin thorough the F7 filters on the top is included in the price. Frequency controlled. By the help of blowing fan inverter and pressure transmitter air pressure can be fixed at same level automatically. Overspray Filtration Overspray is sucked through dry filters: the operating maintenance costs of this system are reduced to minimum. The large filtering surface area guarantees better air distribution, which translates into uniform finishing and a cleaner machine. Snail Exhaust Fan with a capacity of 12.000 m3/h is included in the price. Optional Water Filtration System Culverts exhausting the dusty air in the cabin is produced with water curtain. Recommended for UV Systems. Control Panel: has an electric control panel with PLC and machine control software, controlled by a 10″ colour touch screen. Automatic Lubrication System This system automatically lubrificates lineer bearings and guides of the reciprocating arms. VPN REMOTE ACCESS Producer and customer can check the machine, access the production reports, alarms and outputs through internet. OPTIONAL FEATURES I TWO-ARM RECIPROCATING SPRAY COATING MACHINE In this system, all kind of data about working and defects on machine is recorded momentarily on the all KAMA machines so that it helps to its user using the gained informations. So you can see momentarily the working status of your machine and get information about the defects experienced. You can check who worked how long and production volume during operation and past reports with details. You can get specific reports when you filter the parameters on data given. Furthermore by setting up the different type of alarms you can perform your work status without problem. REMOTE TECHNICAL SUPPORT SYSTEM WITH INCREASED REALITY With the Vsight Remote application, which we offer our remote technical service much more quickly and praccally, we greatly prevent the downtime that may occur during the use of our machines. Your machine operator can instantly connect to the technical service officer at the KAMA headquarters with a smartphone, tablet or smart glasses. In this way, the necessary intervention can be made within seconds with voice and video call problem malfunctions, marking and voice commands on live video. TECHNICAL SPECIFICATIONS Weight : 3.800 Kgs Dimensions : L: 3900 mm, W: 3680 mm,H: 2650 mm Elektric Consumption : 14,20 Kw/h Total Pressurized Air Requirement: 7 Bars,1100 liters/min. (60 NL without guns) Aspiration Fa

KR BM 1000-K has been designed and developed to provide the user convenience as well as obtaining a high quality machined surface of all kinds of panel materials. Our Automatic Spraying Machine provides fast painting of materials such as wood, glass, plastic, metal, fibercement at low cost. KR BM 1000 K Automatic Spraying Machine has been designed to achieve high quality finishing on any kind of panel material together with an ease of operation. With the paper belt system, it provides easy color changing in a short period of time. This feauture makes KR BM 1000 K a good choice for small and middle tier companies. Materials such as wood, glass, plastic, metal, fibercement etc. can be painted very fast with lower costs by KR BM 1000 K. Reader Sensor System Scanner bars in the Reader Sensor System located at the entrance of the KR BM 1000-K perceive the dimensions and shape of the product to be painted and introduce it to the automatic painting machine with millimetric precision. So, by ensuring that the paint is applied only to the product, it prevents waste by controlling the amount of paint used and provides savings. Painting System I Automatic Spray Machine Our machine has a highly developed system. Painting process is done with a robot arm placed in the center and equipped with 4 high-pressure paint spray guns. The arm speed, which can be adjusted from the control panel, can be operated up to 180 meters per minute if desired.The paint spray guns can be changed easily and angle and height can be adjusted thanks to its user-friendly design. The material to be sprayed is divided into microns and applied to the product at the right speed and pressure thanks to the high-pressure paint spray pump. The arm speed can reach a maximum of 180 m / min. Pump: 1 pc high pressure pump Guns: 4 pcs high pressure guns Paper Conveyor Belt System KR BM 1000-K paints products on a paper belt on a vacuum conveyor belt. The paper belt is always tense, stable and smooth during painting and does not wrinkle thanks to the vacuum conveyor. After the painting process, the dirty paper is released from the mechanically braked system and it is easily wrapped on a roll at the exit of the machine with the torque-controlled winding system. GUN PLATE SYSTEM The KR BM 1000-K painting arm is designed to allow easy replacement of the paint sprayer gun system.Thanks to this feature, color transitions can be made very quickly. When detailed cleaning is required, it can be disassembled and installed in a short time and the cleaning of the spraying machine can be made within minutes. Ventilation system In our Spraying Machine, thanks to the paper filter exhaust system in the cabin, after the clean air coming from the machine is polluted, it passed through the paper filters on the sides and thrown out. Keeping the flow direction of the air inside the machine under control and removing it from the environment provides you with optimum painting opportunity. Touch Control Panel You can easily adjust the height and depth of the products to be painted, the amount of paint to be used and all the settings such as fan speed, conveyor belt speed, robot arm speed with the touch control panel on the KR BM 1000-K Automatic Spray Machine. OPTIONAL FEATURES I AUTOMATIC SPRAY MACHINE In this system, all kind of data about working and defects on machine is recorded momentarily on the all KAMA machines so that it helps to its user using the gained informations. So you can see momentarily the working status of your machine and get information about the defects experienced. You can check who worked how long and production volume during operation and past reports with details. You can get specific reports when you filter the parameters on data given. Furthermore by setting up the different type of alarms you can perform your work status without problem. REMOTE TECHNICAL SUPPORT SYSTEM WITH INCREASED REALITY With the Vsight Remote application, which we offer our remote technical service much more quickly and praccally, we greatly prevent

KR BM 600 Wood Profile Painting Machine is a new generation profile painting machine which differs from its equivalents with its wide cabin, economical paint recovery system and its ability to be integrated into automatic loading & unloading systems. STANDARD FEATURES I PROFILE PAINTING MACHINE Conveyor Belt with Paint Recovery System The paint recovery system on KR BM 600 Wooden Profile Painting Machine, which saves between 20% and 30% material, is offered as standard. Pump and Guns KR BM 600 Automatic Profile Painting Machine has 1 diaphragm pump and 4 low pressure automatic spray guns with adjustable positions are presented as standard. Cartridge Exhaust Filter A removable cartridge exhaust filter, which enables the adjustment of the paint spray guns and the cleaning of the cabin, is provided as standard in the KR BM 600 Profile Painting Machine. OPTIONAL FATURES High Pressure Pump and Guns KR BM 600 Profile Painting Machine s substructure is convenient to install high pressure pump and guns. 4,6 or 8 guns can be installed optionally. Automatic Loading & Unloading Units Automatic loading & unloading units can be added to work in tandem with KR BM 600 Profile Painting Machine. Water Filtration System KR BM 600 Profile Painting Machine for Door Frames can be produced with water filtration system optionally. This system both increases the product quality and protects the enviroment by reducing emission. IoT In this system, all kind of data about working and defects on machine is recorded momentarily on the all KAMA machines so that it helps to its user using the gained informations. So you can see momentarily the working status of your machine and get information about the defects experienced. You can check who worked how long and production volume during operation and past reports with details. You can get specific reports when you filter the parameters on data given. Furthermore by setting up the different type of alarms you can perform your work status without problem. REMOTE TECHNICAL SUPPORT SYSTEM WITH INCREASED REALITY With the Vsight Remote application, which we offer our remote technical service much more quickly and praccally, we greatly prevent the downtime that may occur during the use of our machines. Your machine operator can instantly connect to the technical service officer at the KAMA headquarters with a smartphone, tablet or smart glasses. In this way, the necessary intervention can be made within seconds with voice and video call problem malfunctions, marking and voice commands on live video. TECHNICAL SPECIFICATIONS Dimensions: W: 2.970mm H: 2.230mm L: 3.950 mm Weight: 1800 kg Electricity consumption: 7,75 kW/h Conveyor Working Speed (Max): 25m/dk. Part Size to be Painted (Max): W: 350mm H: 250mm L: Unlimited Dry Ventilation Flow (Max): 12000 m3/h Supply Air Pressure: 6 Bar Number of Paint Guns: 4 Pcs. Effective Bandwidth: 500 mm Areas of Usage: Door case, Door Frame, Baseboard, Wood Profiles

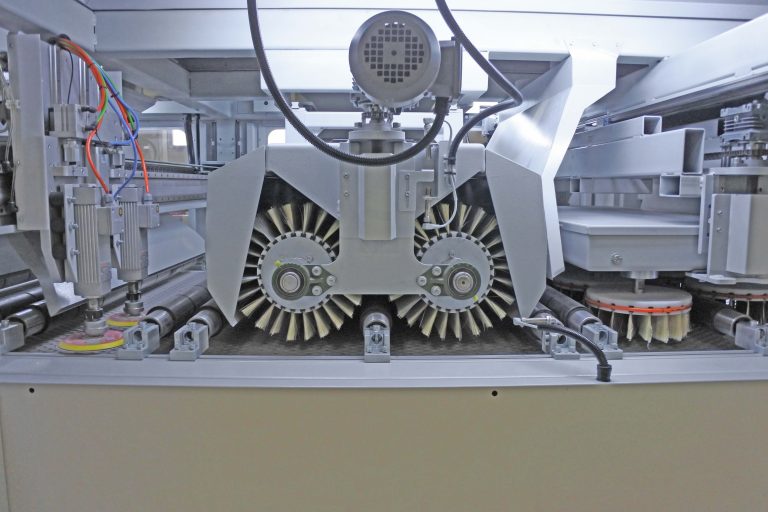

KR YZM 1300 Surface Sanding Machine is a highly sensitive sanding machine to developed to sand the raw and primed surfaces and carvings of doors, covers and modular furniture parts. Fine sanding can also be done before polishing with our KR YZM 1300 Automatic Surface Sanding Machine. STANDARD FEATURES SURFACE SANDING MACHINE Oscillatory Orbital Sander System: There are 8 moving orbital vibration sanding motors with automatic adjustment of pressure forces and distances in our Oscillatory Sanding Machine. By the help of high precision mapping; these independent working units do smart abression and obtain a high quality surface by considering the edges of the product and thickness differences on the surface. Oscillatory Disc Brush System: This Automatic Sanding Machine has a unit consists of 9 oscillating brush sanders with automatic height and speed adjustment. Raw or primed carved, rustic work surfaces can be sanded succesfully by these brush sanders. In addition, these disc brushes on the unit can be changed easily. Oscillatory Cylinder Brush System: This system on the KR YZM 1300 Wood Sanding Machine consists of 2 cylinder brush sanders with automatic adjustment of height and rotation speed. It provides sanding raw or primed carvings on the product surface with Furniture Sanding Machine. Easily changeable brushed provide convenience to the operator. Nonwoven Flap Cylinder: Nonwoven flap in the Door Sanding Machine removes the sanding scratches from the surfaces of the finished products and provides a very smooth surface by making superfinish. As the nonwoven flap cylinder is exhausted, it can be easily adjusted mechanically. OPTIONAL FEATURES Steady Vibrations It consists of 6 oscillating orbital sanders on which pressure forces and distances can be adjusted automatically on this unit. The system, which is used for sanding before polishing, to make the surface homogeneous, can also be used for primer sanding. Wider Machine The KR YZM 1300 Wood Sanding Machine can be manufactured in accordance with the 1500 mm sanding width, optionally. IoT In this system, all kind of data about working and defects on machine is recorded momentarily on the all KAMA machines so that it helps to its user using the gained informations. So you can see momentarily the working status of your machine and get information about the defects experienced. You can check who worked how long and production volume during operation and past reports with details. You can get specific reports when you filter the parameters on data given. Furthermore by setting up the different type of alarms you can perform your work status without problem. REMOTE TECHNICAL SUPPORT SYSTEM WITH INCREASED REALITY With the Vsight Remote application, which we offer our remote technical service much more quickly and practically, we greatly prevent the downtime that may occur during the use of our machines. Your machine operator can instantly connect to the technical service officer at the KAMA headquarters with a smartphone, tablet or smart glasses. In this way, the necessary intervention can be made within seconds with voice and video call problem malfunctions, marking and voice commands on live video. TECHNICAL SPECIFICATIONS Total Weight: 5.310 Kgs Dimensions L: 5490 mm W: 2440 mm H: 1900 mm Total Electrical Demand : 20 kw/h Total Compressed Air Consumption: 260 L/m Max. Product Length: Limitless Max. Product Widt: 1300 mm Max. Product Height: 70 mm Min. Product Lenght: 350 mm Min. Product Width: 150 mm Min. Product. Height: 3 mm Max. Operating Speed: 8 m/min Max. Robot Arm Speed: 120 m/min Sand Paper Grit Range: P80 P2000 Working Direction : Left Usage Areas: Doors, covers, modular furniture parts

KR FZM 1300-2 Automatic Sanding Machine which is developed to sand raw, primer or filling applied rustic, carved, flat surfaces achieves successful results even on the most difficult surfaces thanks to its flexible sanding feature. STARDARD FEATURES The KR FZM 1300-2 Brush Sanding Machine offers its user high quality and economical surface sanding opportunities even on very difficult products with its standard features whihc do not exist in many machines. Conveyor Table The conveyor table reciprocates up and down and the position can be changed for the part thickness with 0.1 mm precision. This change of position can be made between 0-75 mm. Max. part thickness can be adjusted to 70 mm. This process is done automatically on the touch panel. Vacuum Conveyor Table The Vacuum Conveyor Table of our Brush Sanding Machine ensures that the parts to be sanded remain stable without slipping on the belt. We achieve the best results by using the vacuum system so that small workpieces do not move by the sanding brushes and can be sanded correctly. Oscillatory Disc Brush System This unit consists of 9 oscillating brush sanders with automatic adjustment of height, speed and direction. There are 2 units of this system in total. It is extremely successful in raw and primer sanding of carvings on the product. Easily replaced brushes provide convenience to the operator. Its ability to rotate both sides allows the use of different grits on 2 surfaces on our automatic brush sanding machine. Oscillatory Cylinder Brush System Our Oscillating Sanding Machine has 6 cylinder brush sanding units with automatic adjustment of height, rotation speed and direction. The carvings on the product are sanded with raw and primed. Easily replaceable brushes provide convenience to the operator. Its ability to rotate in two directions allows the use of different grits on 2 surfaces. Touch Control Panel The positioning of all units (how far the brush sander plunges into the workpieces), the working direction of the sanders, the rotation speed of the sanders and the positioning of the conveyor table are done on the touchscreen control panel with the KR FZM 1300-2 Sanding Machine for Wood. These features are registered under a name with the prescribing system. Later these configurations can be called for use over that name. OPTIONAL FEATURES In this system, all kind of data about working and defects on machine is recorded momentarily on the all KAMA machines so that it helps to its user using the gained informations. So you can see momentarily the working status of your machine and get information about the defects experienced. You can check who worked how long and production volume during operation and past reports with details. You can get specific reports when you filter the parameters on data given. Furthermore by setting up the different type of alarms you can perform your work status without problem. REMOTE TECHNICAL SUPPORT SYSTEM WITH INCREASED REALITY With the Vsight Remote application, which we offer our remote technical service much more quickly and praccally, we greatly prevent the downme that may occur during the use of our machines. Your machine operator can instantly connect to the technical service officer at the KAMA headquarters with a smartphone, tablet or smart glasses. In this way, the necessary intervention can be made within seconds with voice and video call problem malfunctions, marking and voice commands on live video. Extra Working Width / Height The KR FZM 1300-2 Furniture Sanding Machine can be manufactured in accordance with a sanding width of 1500 mm as optionally. The KR FZM 1300-2 Automatic Surface Sanding Machine can be manufactured to suit the 200 mm sanding height upon request. TECHNICAL SPECIFICATIONS Total Weight: 5310 KGS Dimensions: L: 5820 mm W: 2300 mm H: 1910 mm Total Electrical Consumption: 20 Kw/h Total Compressed Air Demand: 260 L/m Max. Product Length : Limitless Min. Product Length: 350 mm Max. Product Width: 1300 mm Min. Product Width: 150 mm Max. Product Height: 7

No represented companies found.

- KA-MA KARABUDAK MAKİNE

TR

TR