| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

UNİMAK MÜH. HIZ. VE MAK. SAN. TIC. LTD. STI.

Tuzla Kimya Sanayicileri OSB Analitik Cad. No: 40 34953 Aydınlı Tuzla / / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 593 1580

|

Hall: 7

Stand: 713

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

UNIMAK, with 58 years of experience on machine production and its expert staff, produces and constantly develops systems which integrates production with automation such as wide surface lamination and wrapping lines, furniture profile wrapping, frame-casing, edgeband slitting, protective tape slitting, loading-unloading systems, full automatic frame-casing and profile production lines requested by woodworking industry. For continuous customer satisfaction, starting from constant training and development philosophy, UNIMAK proceeds to increase its capacity and employee quality, with its team formed with experienced engineers and technicians. By following the developments in the wrapping and slitting technologies at the right time and earning its prestige, UNIMAK has become the most preferred brand over 90 countries in the world.

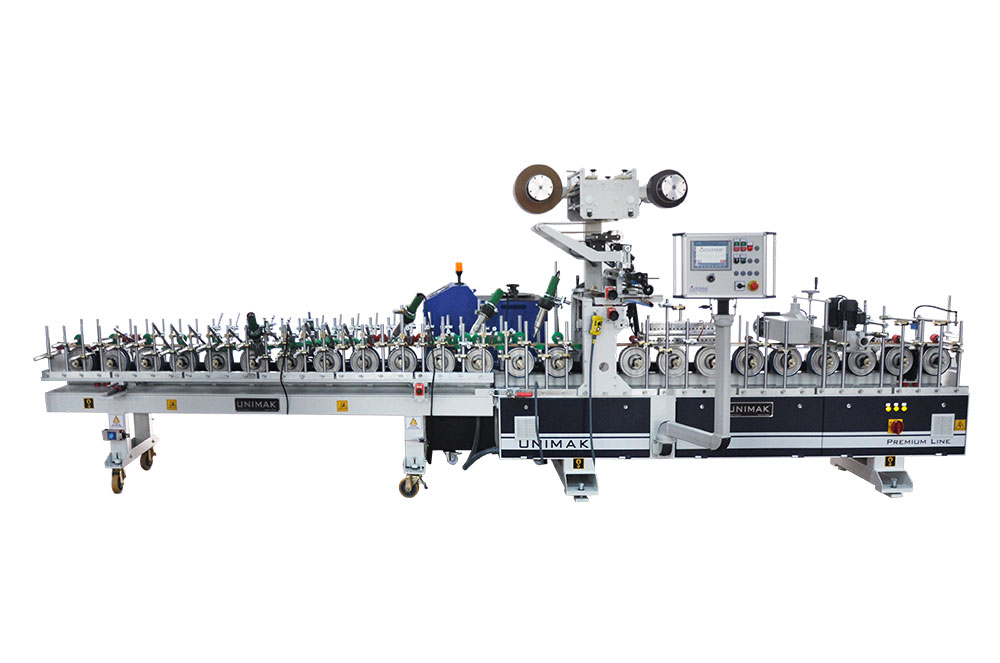

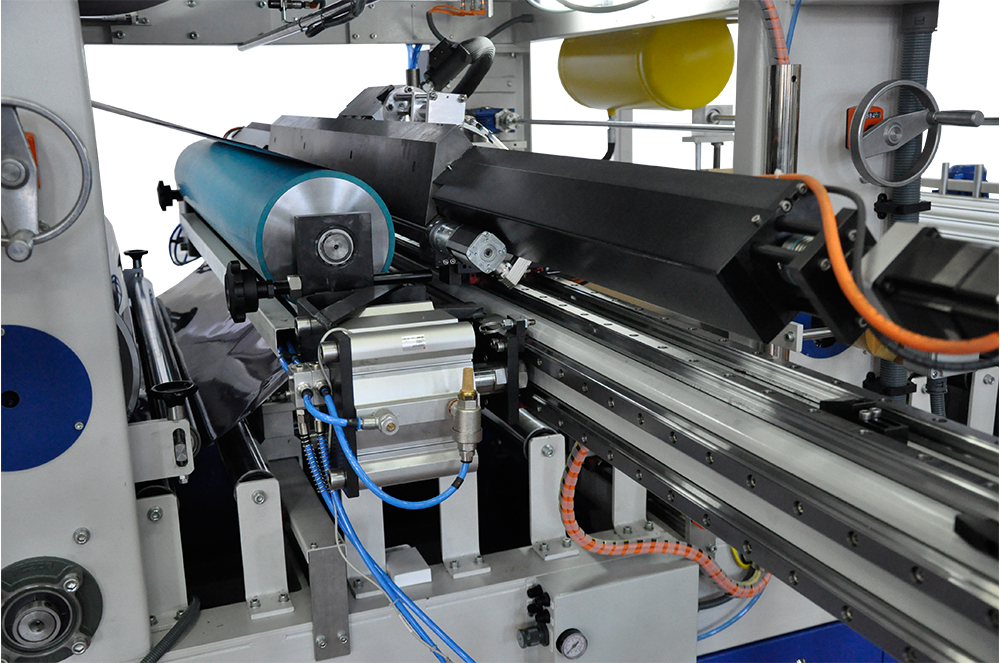

Profile wrapping machine wraps PVC, finish foil, CPL (micro laminate), high gloss and P.P. foils to MDF, wooden profile, wall panels, frame and casing with Polyurethane (PUR) hotmelt glue system via slot nozzle.

Profile wrapping machine wraps natural veneer, finish foil, P.P., PVC and CPL (micro laminate) foils (roll or papel) to MDF, wooden profile, wall panels, frame and casing with Polyurethane (PUR) and EVA / PO Hotmelt System (VMM) and glue applying roller.

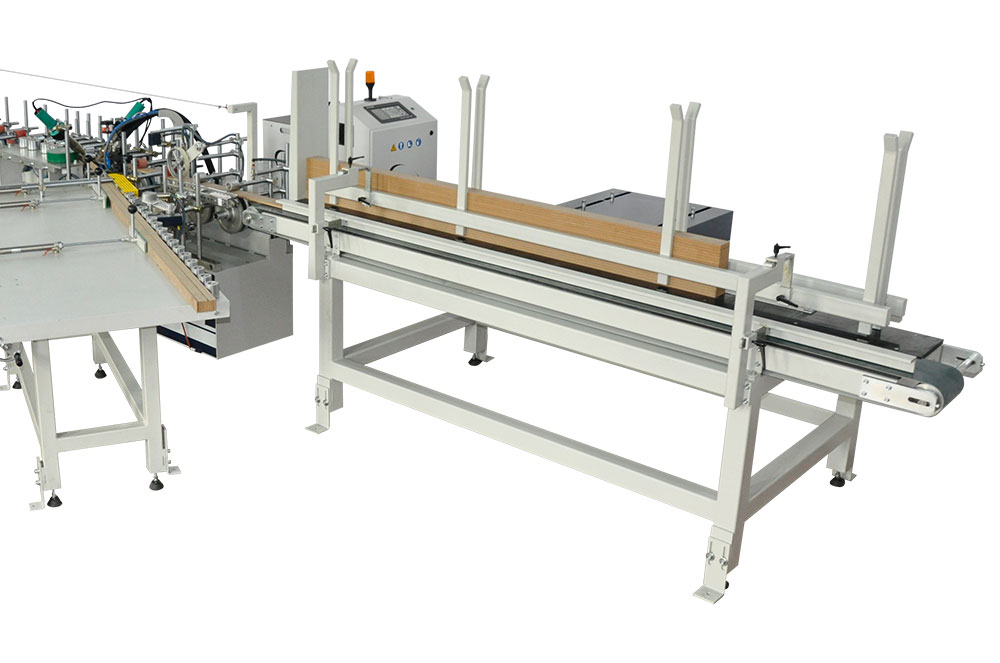

Full automatic L-casing production line merges various type of door casing s main profile to sidelath by 90°, using polyurethane (PUR), polyolefin or EVA hotmelt adhesives.

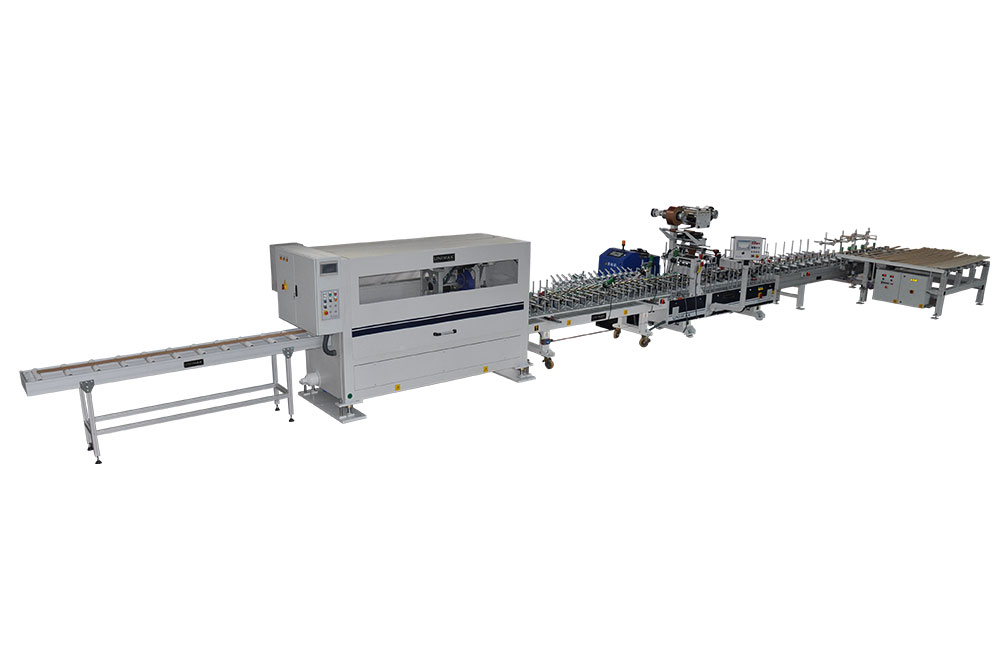

To increase productivity on high speed production lines profiles fed automatically to lamination machine. Full Automatic Profile Lamination Lines make profile ready by laminating PVC, finish foil, CPL (micro laminate), high gloss and P.P. foils to MDF, wood, panel, door frame and door jam on Profile Wrapping Machine with Slot Nozzle and Polyurethane (PUR) Hotmelt application system then specially designed Flying Saw with Servo system finds and cuts automatically joint of two wrapped profiles.

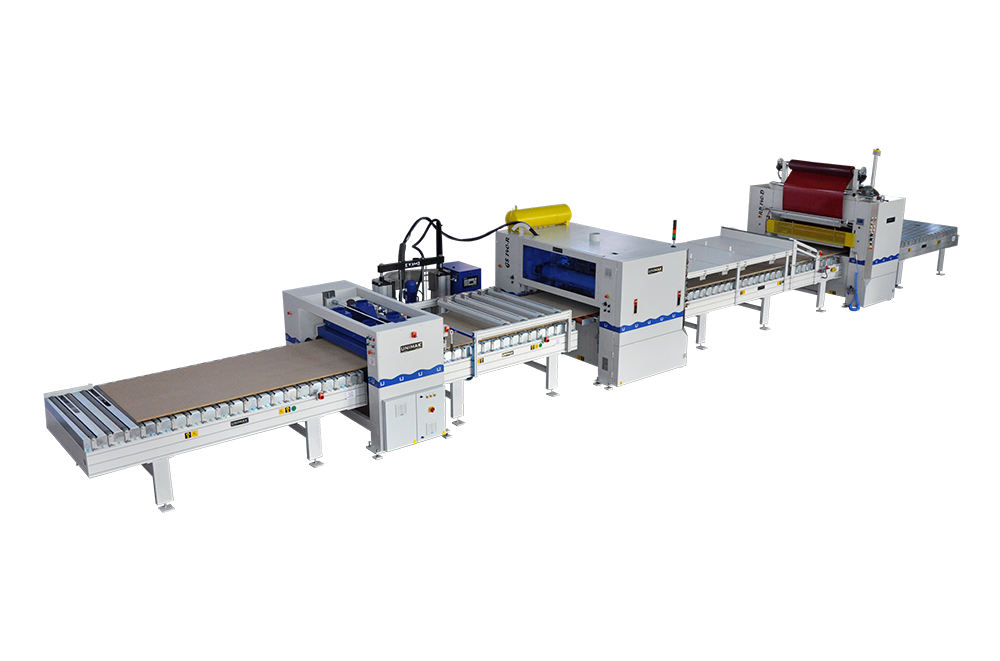

Lamination lines, laminates surfaces up to 1350 mm width such as MDF, chipboard, wall panel (sanded panels), XPS and EPS polystyrene sandwich panels etc. with REVERSE roller equipment for high gloss lamination to the materials that are suitable for sheet or roll type lamination such as acrylic, P.P., ABS, PET, finish foil, laminate, natural veneer with an external Polyurethane (PUR) hotmelt adhesive melting systems.

Manipulators are designed for continuous form lamination with integrated loading robot in the panel lamination line and stacking laminated products with unloading robot. It has the capacity of loading or stacking panels from minimum 3mm thickness to maximum 60mm thickness with panel loading or unloading grippers. Security fence provides maximum security measure during operation.

Wide surface lamination machine laminates foils in roll form such as PVC, high gloss, finish foil, CPL (micro laminate), up to maximum 130 cm foil width to MDF panels, chipboard, wall and furniture panels with using Polyurethane Hotmelt (PUR) Glue.

Machine is designed for electronically finding and cutting joints decorative foil in roll form on lamination lines for all sorts of high gloss panel, wall panel and door leaf. CEC 130 coded left-right edge trimming system provides trimming for excess edges and after trimming to prevent any dust inside the factory area, excess parts are collected automatically by spool system.

Slitting machine slits PVC and P.P. foil bobbins up to 0.40mm thickness and in 700mm or 1500mm width.

Slitting machine slits edge band up to 1 mm thickness with top-bottom rotary knife system.

No represented companies found.

The company has no registered brand information.

TR

TR